The Crucial Guide to Comprehending Screen Printing and Its Versatile Uses

Screen printing has a rich history that dates back to old times, developing right into an advanced method utilized across different sectors today. This overview explores the intricacies of the screen printing process, detailing its applications in home, advertising, and fashion decoration - 10:9 Design Texas. Understanding these fundamentals can open up creative potential for both commercial and creative tasks. The following areas will expose essential ideas and techniques to boost one's screen printing undertakings

The History of Screen Printing

Screen printing has origins that map back centuries, its advancement mirrors the technical and imaginative advancements of numerous cultures. Originating in old China, the technique was at first utilized for embellishing fabrics and later infect Japan, where it came to be essential to Ukiyo-e woodblock printing. The approach shifted to Europe in the 18th century, where it gained popularity among artisans and business printers. The development of image emulsion in the 20th century transformed screen printing, permitting even more intricate styles and greater efficiency. Artists like Andy Warhol even more thrust its popularity, making use of the tool to develop renowned jobs that combined commercialism and art. By the late 20th century, screen printing had developed itself as a functional strategy, employed in vogue, advertising, and fine art. Today, it remains to develop, integrating digital technology and expanding its applications throughout different markets.

The Screen Printing Process Explained

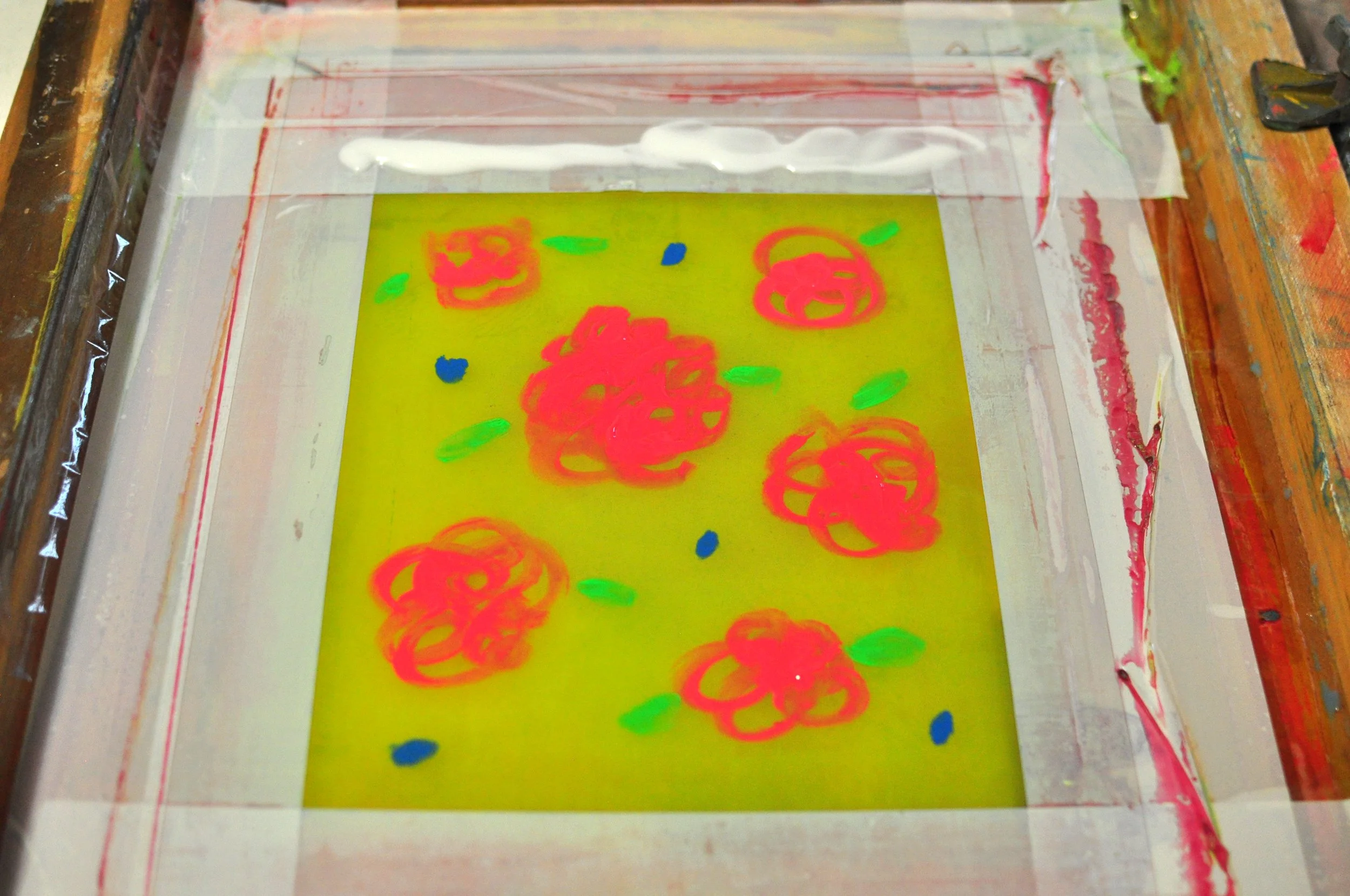

Screen printing transforms creative visions into substantial designs via a series of precise actions. A picture is created and then transferred onto a screen, normally made of great mesh material stretched over a frame. A light-sensitive solution is applied to the screen, which is subjected to light, setting in areas not covered by the photo. After rinsing the unhardened solution, a pattern is formed.

Next, the screen is put over the substratum, whether it be textile, paper, or an additional product. Ink is after that pushed with the open areas of the pattern using a squeegee, depositing the layout onto the substratum below. This procedure can be repeated for several shades, needing separate displays for each and every hue. Finally, the published product is healed using warm to guarantee the ink sticks properly, leading to a durable, vibrant design all set for use.

Kinds Of Screen Printing Techniques

Furthermore, specialized techniques, such as discharge screen printing, get rid of color from the textile to create softer prints, while foil screen printing applies metallic foil to accomplish a shiny finish (10:9 Design contact). Each method offers distinct attributes, accommodating different imaginative demands and production scales, ultimately expanding the possibilities within the screen printing domain name

Applications of Screen Printing in Various Industries

Additionally, the signage and marketing markets use screen printing for producing appealing display screens and banners. This approach permits bold colors and detailed layouts that catch focus. In electronics, screen printing is used for applying conductive inks to motherboard, crucial for element connections. Moreover, the home design industry accepts screen printing to create distinct styles on textiles and wall surface art. Overall, screen printing acts as a crucial tool throughout diverse fields, boosting items with customized and aesthetically appealing graphics.

Tips for Effective Screen Printing Projects

While carrying out a screen printing task, cautious interest to detail can substantially improve the last outcome. Initially, choosing premium materials is vital; this includes the screen, inks, and substrates. Using ideal mesh counts can influence ink deposition and information resolution. Preparation is similarly crucial; comprehensive cleansing of screens and appropriate direct exposure times assure crisp prints.

Next, exact enrollment is critical for multi-color prints. Making use of alignment tools can help accomplish precise layering. In addition, testing prints on scrap products prior to manufacturing aids determine potential issues without wasting sources.

Regularly Asked Concerns

What Materials Are Best for Screen Printing on Fabric?

Cotton and polyester blends are excellent for screen printing on textile because of their durability and ink absorption. Furthermore, specialty materials like silk or canvas can generate unique appearances and surfaces, enhancing the overall style quality.

Just how Do I Tidy and Maintain Screen Printing Tools?

To clean and keep screen printing tools, one need to regularly wash displays with appropriate solvents, evaluate mops for wear, lube relocating components, and shop all things in a completely dry, dust-free setting to lengthen their life-span.

What Are the Environmental Influences of Screen Printing?

Screen printing can have significant ecological influences, including chemical waste from solvents and inks, water usage throughout cleansing processes, and energy usage. Eco-friendly products and lasting methods are crucial for reducing these negative results.

Can Screen Printing Be Done at Home Efficiently?

Screen printing can be successfully done at home with the ideal products and strategies. Hobbyists can produce high quality prints, though success relies on their ability level, devices, and understanding of the process entailed.

What Are the Costs Associated With Beginning a Display Printing Company?

Beginning a screen printing service involves prices for tools, materials, and workspace. Preliminary costs normally range from a couple of hundred to a number of thousand dollars, depending upon the range, quality of machinery, and desired production capability.

Screen printing has a rich history that dates back to more info ancient times, developing into an innovative technique utilized throughout numerous industries today. One more technique, rotary screen printing, utilizes cylindrical displays, facilitating continual printing on textile rolls, consequently improving effectiveness for large productions. In addition, specialty methods, such as discharge screen printing, eliminate dye from the textile to develop softer prints, while aluminum foil screen printing applies metallic foil to accomplish a shiny coating. In the fashion field, screen printing is commonly used to create vivid styles on garments, enabling brands to display their distinct designs. Cotton and polyester blends are perfect for screen printing on fabric due to their durability and ink absorption.